view our product lines | CHESTERTON | INPRO/SEAL | ENVIROSEAL | PUMPS

Industrial equipment faces adverse environmental conditions that attack metallic components and structures, resulting in compromised plant reliability and safety, and loss of profits. When facing these conditions you need to select not only a great product like ARC, but also a great company to stand by you. Progressive Sealing understands your specific needs and can make recommendations for the best long-term solution. When cementitious or metallic surfaces are subject to aggressive industrial application environments, you can rely on us.

We offer zero VOC, 100% solids composites for use in a broad spectrum of industrial applications such as:

✓ Emergency repairs and resurfacing

✓ Erosion/corrosion at elevated temperatures

✓ Impact and aggressive sliding abrasion

✓ Severe chemical immersion and corrosive vapour exposures

Progressive Sealing and Chesterton have been protecting critical structures and equipment with ARC Advanced Industrial Coatings technology for over 25 years. ARC industrial coatings are scientifically engineered to protect metal and concrete from the damage and costly problems associated with abrasion, erosion, corrosion, chemical attack, and atmospheric corrosion.

By educating ourselves on your needs and critical success factors, we can provide you with the best solution by using:

✓ Site analysis

✓ Product test validation

✓ Proposal development

✓ Application implementation

✓ Project documentation

✓ Review

ARC INDUSTRIAL COATINGS

OUR PRODUCTS

High-build Concrete Resurfacer Coating

Brush & Roll Grade, Chemically-Resistant Coating with Moderate Ceramic Reinforcement

Fine Grade, Sliding Wear Compound

General Purpose, Thin Film, Novolac Blend, Epoxy Coating

High Temperature Corrosion Resistant Coating

Trowel-Grade Coating for Coarse Particle Extreme Sliding Wear and Impact

General Purpose, Sprayable, Corrosion Protection Coating - NSF 61 Certified, NSF 600 Compliant

Corrosion Protection in High-Temperature Immersion

Rapid Cure, Sprayable, Ceramic-Reinforced Coating

Trowel-Applied, Quartz-Reinforced Concrete Resurfacer

Carbon fiber reinforced novolac epoxy laminate repairs for corrosive conditions up to 93C (200F)

Fast-Setting Grout Resurfacer to Repair/Patch Concrete Surfaces

Rapid-Curing, Trowel-Grade Coating for Coarse Particle Severe Sliding Wear with Impact

High Build, Single Coat, Edge-Retentive Barrier Coating

FDA Compliant, Thin Film, Corrosion Resistant Barrier Coating

Fast-Penetrating, Modified-Epoxy Primer/Sealer

Coarse Grade, Sliding Wear Compound

Carbon fiber reinforced novolac epoxy laminate repairs for high temperature conditions

Fast-Setting Grout Resurfacer to Repair/Patch Concrete Surfaces

Abrasion Resistant Coating for Fine Particle Wear

General Purpose, Sprayable, Corrosion Protection Coating

100% Solids, Mineral-Reinforced, Epoxy Novolac, Acid-Resistant Coating

Abrasion Resistant Rebuilding and Faring Composite

Rapid-Curing, Trowel-Grade Coating for Fine-Particle Moderate Sliding Wear

Highly Chemically Resistant, 100% Novolac Resin, Epoxy Coating

Impact- and Wear-Resistant Epoxy Composite

Trowel-Grade Coating for Fine Particle Severe Sliding Wear

Ceramic-Reinforced, Sprayable, Erosion-Resistant Coating

Sprayable, Ceramic-Reinforced Coating

100% Solids, Low Viscosity Amido Amine Cured Epoxy, Ideal for Coating Floors and Aisles

ENGINEERED POLYMERIC SOLUTIONS

Chesterton’s Engineered Polymer Solutions Group is a worldwide manufacturer and distributor of the highest performing polymer seals. They combine their technical expertise with state-of-the-art material technologies to provide industry-leading solutions.

THOSE SOLUTIONS INCLUDE:

✓ Hydraulic and pneumatic seals – High performance wipers, rod seals, piston seals and ancillary devices designed for use in various hydraulic and pneumatic industrial applications.

✓ Rotary seals – High performance rotary seals designed for use in various applications including bearing and gearbox protection.

✓ Spring energized seals – Spring energized polymeric seals designed to solve today’s most difficult sealing challenges.

✓ Custom seals – Custom engineered polymer seals for the most demanding applications.

✓ Service programs – Unique programs developed to address specific end user needs.

OUR PRODUCTS

Patented, Simple Dual-Component, Split Seal Assembly for Hydraulic Sealing

16K Wear Ring Strips (Metric Sizes)

Prevent Metal-to-Metal Scoring

Bidirectional Compression Seal

Design for Slow Rotating Applications Exposed to Large Shaft Runout

33K Lip Seal with Split Design

Split Seal for Bearing and Gearbox Protection

Easy-to-Install, Patented, Split Rotary Seal for Worn Shaft Applications

Elliptical Coil Spring Energized Seals with Constant Lip Load

Split Polymer Labyrinth Seal (SPLS)

Non-Contact Split Rotary Seal for Bearing Protection

18K Split Wear Rings (Inch Sizes)

High-Performance, Replaceable Cylinder Guides

Wipers for Hydraulic and Pneumatic Applications

Advanced Lip Seal

Dual Component System for Bi-Directional Sealing

Unitized, Non-Contacting Seal for Bearing Protection

High Performance, Multi-Purpose V-Rings

Reduce Flush Requirements and Increase Reliability

19K Split Wear Rings (Metric Sizes)

High-Performance, Replaceable Cylinder Guides

Negative Lip U-Cup Seal

Cartridge Design for Sealing Powders and Viscous Fluids

Canned Wiper

Cantilever Spring Energized Seals (SES), Highly Dynamic

Continuous contact, robust spring design for tight sealing; Heavy-duty, High Load Seals

17K Wear Ring Strips (Inch Sizes)

Prevents Metal-to-Metal Scoring

High Performance O-Ring Upgrade for Static Sealing

Provides Even Loading for Optimum Sealing Force

Improve MTBR by Preventing Extrusion Under Pressure

O-Ring for Static Sealing

Helical Wound Design for Slow Speed and Static Applications

Cost-Effective Method of Extending Seal Life

INDUSTRIAL LUBricants & CHEMICALS

Chesterton offers products and total system solutions for production process, facility, and maintenance needs.

✓CLEANERS AND DEGREASERS

A broad range of technologies to meet the demands of maintenance and production cleaning. Designed for efficient performance they reduce the cleaning time while minimizing the impact on the environment and safety of the user.

✓ GREASES AND LUBRICANTS

Specialty lubricants engineered for optimum performance in specific industrial applications. Designed to improve equipment reliability, while reducing energy and product used.

✓mAINTENANCE SPECIALTIES

Broad range of maintenance chemicals to improve the speed and effectiveness of every day maintenance operations, while improving worker safety and minimizing environmental impact.

✓mETAL WORKING FLUIDS

Designed to reduce the total cost of cutting metal, Engineered for long sump life, extended tool life, while minimizing environmental and worker impact.

✓CORROSION CONTROL

Specialty corrosion protection for both metal and concrete. Short and long term protection of metal parts in storage and shipment.

State -of-the -art technologies, environmentally acceptable alternatives and strict quality processes contribute to fulfilling the customers’ expectations:

Increased productivity

Lowered costs

Reduced disposal and labour costs

OUR PRODUCTS

Low Evaporation Rate; Safe on All Metals and Most Plastics

279 PCS Precision Cleaning Solvent

Ultra-High Purity, Non-Flammable Electronic Cleaner

Oil-Based; For All Types of Metal Cutting and Forming

Synthetic Lubricating Fluid—High-Temperature Service; ISO VG Grade: 68

625 CXF Corrosion-Resistant, Extreme-Pressure H1 Food Grease

Superior Water Washout Resistance; NLGI #2, NSF H1

High Performance Electric Motor Grease

690 FG H1 Food-Grade Lubricant

USP White Food-Grade; High-Penetrating Lubricating Oil

723 Sprasolvo® Penetrating Oil

Fast-Acting Pinpoint Spray

Self-Healing, Corrosion-Preventative Compound

775 Moisture Shield Protective Coating

Thin-Film, Moisture-Displacing; Protects Metal from Corrosion

Minimizes friction and wear in extreme pressure applications

900 GoldEnd® Thread Sealant Paste

Lubricates Threads During Assembly and Disassembly; PTFE Fortified

Electro-Mechanical Automatic Grease Dispensers; Dispenses Grease Accurately at Timed Intervals

“Pulse” Delivery; Automatic Lubrication System for Oils

294 CSD Critical Surface Degreaser

Cleans Instantly; Removes Resins, Adhesives and Oily Deposits

Synthetic Lubricating Fluid - High-Temperature Service; ISO VG 460

615 High-Temperature Grease #2

Available in Three Formulations: #1, #2, #2-460

630 SXCF Extreme-Pressure, Corrosion-Resistant Grease

Synthetic, High-Temperature/High Speed, H1 Food-Grade Grease

650 AML Advanced Machinery Lubricant

Advanced Machinery Lubricant

Protects Gears, Sprockets, Chains, and Wire Ropes

725 Nickel Anti-Seize Compound

Lubricates for assembly and disassembly

Reacts with Rust to Form a Protective Film

Ceramic-Based, High Performance Anti-Seize/Thread Lubricant; NSF H1

803 IMS II: Industrial & Marine Solvent

Biodegradable, Water-Based Degreaser for Maximum Efficiency

KPC 820N Water-Based Degreaser

Moderate pH, Industrial, Water-Based Degreaser

276 Electronic Component Cleaner

Non-Ozone Depleting Cleaner

Fast Evaporating, High Purity, Low Residue Electronic Cleaner

Synthetic Lubricating Fluid—High-Temperature Service; ISO VG 220

615 High-Temperature Grease #2 460

Available in Three Formulations: #1, #2, #2-460

635 SXC Synthetic, Extreme-Pressure, Corrosion-Resistant Grease

Exceptional Grease for Electric Motors

652 Pneumatic Lubricant & Conditioner

Restores and Conditions Pneumatic Equipment

720 CCG Chain, Cable, and Gear Lubricant

Extreme Pressure, Water, and Corrosion Resistant; Tacky, Semi-Fluid Grease

Reduces Belt Slippage; Conditions and Prevents Hardening

Premium Nickel Anti-Seize Compound

Ceramic-Based, High Performance Anti-Seize/Thread Lubricant

860 MPG Moldable Polymer Gasketing

Creates Ultra-Thin Gaskets that Conform to Irregular Surfaces

292 PDS® Precision Degreasing Solvent

Fast Acting; Pleasant Odor; Safe for All Metals

601 Chain Drive Pin and Bushing Lubricant

Extends Chain and Wire Rope Life; Reduces Energy Use

615 High-Temperature Grease #1

Available in Three Formulations: #1, #2, #2-460

Synthetic, Corrosion-Resistant Machinery Grease; NSF H1 Registered

High Performance Electric Motor Grease

Protects Gears, Sprockets, Chains, and Wire Ropes

723FG Sprasolvo™ Penetrating Oil

Fast-Acting Pinpoint Spray; NSF H1

High Solids, Pure Zinc, Anti-Corrosion Coating and Primer

783 ACR Corrosion-Resistant Anti-Seize

Extreme Pressure; Water and Corrosion Resistant Lubricant

Seals Tightly; Oxygen Safe; Chemically Resistant

Moderate pH, Industrial, Water-Based Degreaser

Variable Gas, Single-Point Automatic Lubricator

Variable Gas, Single-Point Automatic Lubricator

Advanced technology is the key to Chesterton Mechanical Seal performance. Our customers look to us to provide complete, up-to-date solutions to the full range of pump leakage problems.

With the new, third generation cartridge seals, we have the ability to meet customers’ increasingly stringent emission control needs with greatly extended MTBPM (Mean Time Between Planned Maintenance).

We can now reference emissions in just a few parts per million – well within regulatory compliance limits. Our total line of general service and specialized mechanical seals can fulfill the plant-wide needs of most process industries and a surprisingly cost-effective value. Now, with the new Streamline™ S10 Single and S20 Dual Seals we can offer plant-wide fluid sealing needs in one set of seals. But the S-Series goes beyond the basics of fluid sealing, to address the economies of total sealing workflow. S-Series will streamline inventory, simplify seal selection, reduce installation complexity and minimize total maintenance costs.

Chesterton’s Engineered Solutions cell can also provide out-of-the-box thinking for difficult to seal and custom applications.

If there isn’t a seal available off the shelf for your needs, we can easily design and build one to suit. Any of the following seals can be designed for your application:

Split Seals

Gas Seals

Bellows Seals

Slurry Seals

Mixer Seals

Component Seals

Seal Support Tanks and Systems

OUR PRODUCTS

Long-Lasting Component Dual Seal

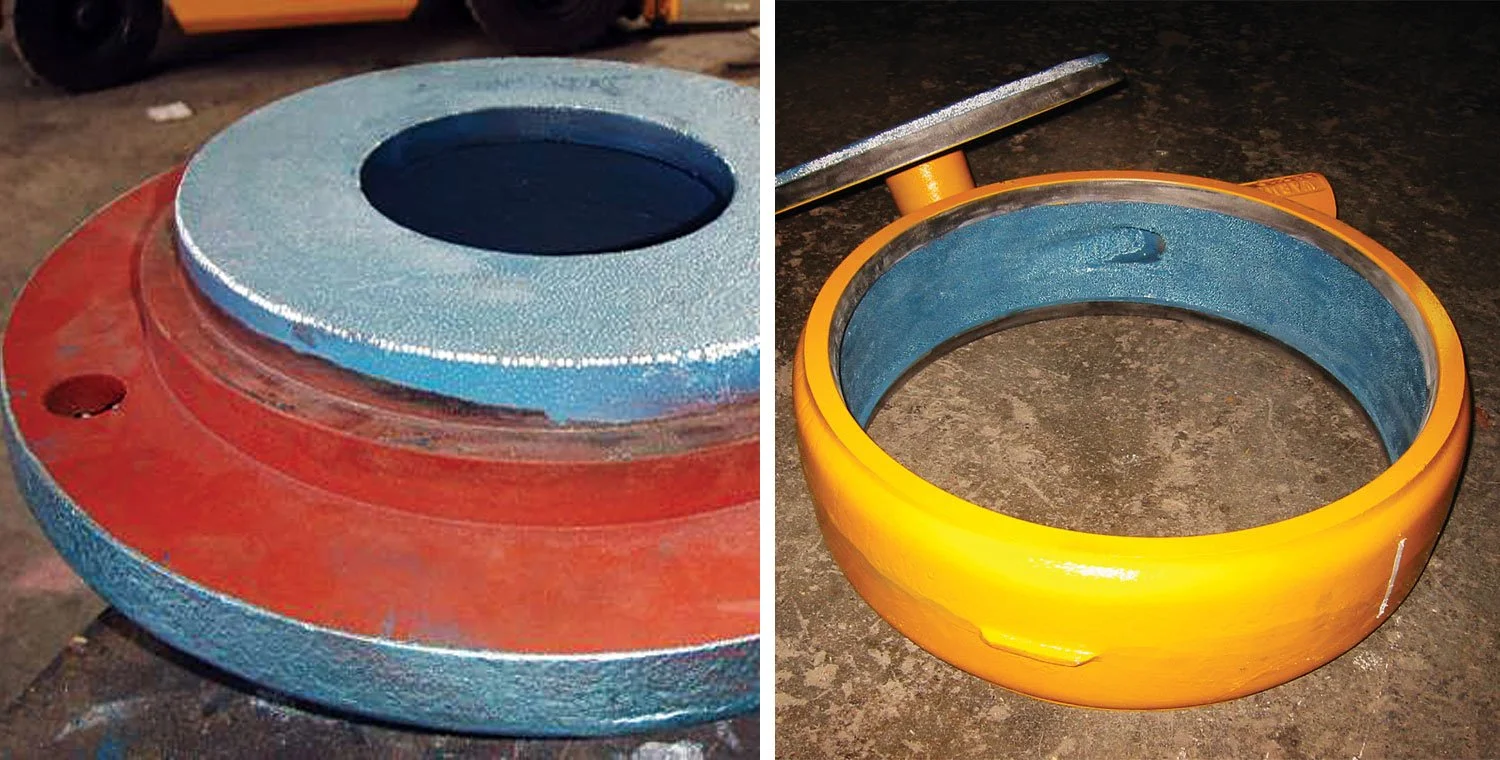

Designed to fit Weir Warman® AH® Pumps

General Purpose Double Cartridge Seal

440/440M External Single Component Seal

Designed for Corrosive Service and Metallic-Free Applications

491 DIN Rotary INternal Single Seal

General Purpose, Single Component Seal

Plan 52 Non-Pressurized Tank

High Performance Single Cassette Seal

Plan 53P Automatic Water Support Tank

General Duty Single Cartridge Seal

Heavy Duty Single Cartridge Seal

General Duty Double Cartridge Seal

Accommodates Loss of Barrier Gas for Greater Sealing Reliability

491 DINS-DINL Rotary Internal Single Seal (EMEA)

Manufactured Specifically for European/Middle East/Africa

Keep Dual Seals Running Cool and Reliably

High Performance Cassette Tandem Double Seal

General Duty Single Cartridge Seal

Heavy Duty Modular Single Cartridge Seal

Heavy Duty Double Cartridge Seal

Split Mechanical Seal

886HT High-Temperature Metal Bellows Single Seal

Designed for High-Temperature Services

Complete Pressurized Tank Solution

Self-Aligning Stationary Seal (SAS)

Easy Installation; Compensates for Equipment Misalignment

Designed to Extend the LIfe of Slurry Pumps

Tandem Double Cartridge Seal

Heavy Duty Modular Double Cartridge Seal

Cartridge Split Mechanical Seal

High-Performance, Single Component Seal

For Sealing Where Axial Space is at a Premium

Install with Mechanical Seals/Packing for Effective Removal of Solids and Improved Cooling

Not Sure What You’re Looking For? Contact Us

PACKING & GASKETING

Chesterton is a worldwide manufacturer and distributor of the highest performing sealing devices including pump and valve packings, pump sealants, live loading technology, sheet gaskets, joint sealants and metal gaskets for a wide range of applications.

While packing and gasketing are considered by some to be technologies of the past, they can still provide a technological advantage even over seemingly more-advanced products. Chesterton has demonstrated this with their incredibly broad installed base and the ability to continuously research and advance the state-of-the-art for these technologies.

Our advanced packings provide such benefits as substantial water reduction, superior leakage and emissions control, the ability to operate at high pressures and speeds, and the ability to withstand process chemicals and reduce sleeve and stem scoring. Our sheet gasketing features high stability, reinforced synthetics that provide excellent sealability and superior reliability.

Our joint sealants provide long lasting high reliability seals that are fast and easy to use. Chesterton Live Loading technology has become the worldwide standard for long-term, low-emissions, low-maintenance packing.

OUR PRODUCTS

Advanced, Reinforced Exfoliated Graphite Packing

Low E Packing for Exceptional Emissions Control

Glaze-Resistant General Service Packing

Heat-Dissipating, High-Grade Carbon Yarn Packing

High-Pressure, High-Temperature Graphite Sheet With Nickel Foil Reinforcement

Flange Live Loading

High Performance, Semi-Metallic Gasket

Severe Slurry Packing

Excellent Emission Performance in an All-Around General Plant Gasket

Flush Management Combination Set

Food Process Packing

Chemical Packing

High-Temperature Carbon Fiber Sheet

Easy Installation in Stuffing Box

Die-Formed Graphite Wedge Low Friction Sealing Rings

Flushless Injectable Packing System made for Food Processing

PTFE Sheet Gasket

Reinforced Graphite Steam Service Packing

Superior General Service Pump Packing with High Chemical Resistance

Slurry Packing

Graphite Sheet with Nickel Reinforcement

Reduces Valve Leakage

Control Valve Packing Set That Outperforms ISO 15848 Standard by More Than Three Times

Flushless Injectable Packing System

Interbraided Exfoliated Graphite Packing for Pumps and Valves

Encapsulated Within the Stainless Steel Metal Carrier, Enhanced Reliability

High Quality, Interbraided PTFE Valve Packing

Silicone Core Packing; Withstands Radial Shaft Motion and Vibration

Superior Carbon Fiber Packing

Carbon Fiber Packing

5505H High-Strength Disc Springs

Flange Discs

Cartridge Live Loading Assembly (CLL)

Engineered Valve Sealing Solution for Improved Reliability and Ease of Maintenance

High Performance Multi-Purpose Packing

High Performance, Semi-Metallic Gasket

Maximize Performance with AMPS™ Active Loading Technology