view our product lines | CHESTERTON | INPRO/SEAL | ENVIROSEAL | PUMPS

The Inpro/Seal Air Mizer® is a complete non-contacting shaft seal designed to prevent product loss, harmful emissions and contamination over the lifetime of your rotating equipment.

Product loss and contamination can be costly – resulting in downtime, unsafe working conditions, and maintenance nightmares. The Air Mizer® uses a positive purge as the sealing medium to create an effective seal without any wearing contact surfaces.

Slow-speed and low-pressure applications challenge traditional shaft sealing methods. Only the Inpro/Seal Air Mizer® fully articulates to accommodate shaft deflection, run-out, axial displacement and misalignment.

Patented shaft seal design creates a barrier for powders, liquids and bulk solids. Here’s how: Small amounts of air, gas or water pressure to create a positive purge against the shaft – permanently sealing against contamination and product loss.

AIR MIZer®

Features & Benefits:

Custom-engineered for your application

Non-contacting, non-wearing design

Energy efficient with low air use

Handles shaft movement and misalignment

Easy-install split designs

FDA-compliant stainless steel options

Lifetime sealing – no rebuild kits needed

Same-day shipping on most products

Backed by a performance guarantee

Sentinel Floating Brush Seal

Reduce steam loss. Extend turbine life. Eliminate carbon ring headaches.

The Sentinel Floating Brush Seal is a high-performance replacement for traditional carbon rings in process steam turbines. Designed for easy retrofitting, it significantly reduces steam leakage—by up to 80%—and lasts 3 to 4 times longer than carbon rings.

Specs at a Glance:

Handles temps up to 1100 °F (593 °C)

Rated for 150 psid and 160 ft/s surface speed

Fits shaft sizes from 0.5″ to 6″

Made from Haynes® 25 cobalt alloy

Ideal for turbines in power, pulp & paper, petrochemical, and similar industries.

Upgrade to a more reliable, efficient sealing solution—Sentinel FBS.

Key Benefits:

Extended Life: 3–4 years of reliable service vs. 6–12 months for carbon rings

Less Steam Loss: Cuts leakage by up to 80%

Simple Retrofit: Split-ring design installs without rotor or casing modifications

Protects Carbon Rings: Shields downstream components from pressure and contamination

Backed by Warranty: 2-year performance guarantee

Protect Bearings. Prevent Failures. Extend Equipment Life.

Inpro/Seal’s Shaft Grounding solutions protect motors and connected equipment—especially those using variable frequency drives (VFDs)—from damaging electrical currents that cause premature bearing failure.

Key Benefits:

Prevents Electrical Discharge Damage: Diverts harmful shaft currents away from bearings

Extends Motor Life: Reduces fluting, frosting, and costly downtime

Zero Maintenance: Durable design with long-lasting performance

Flexible Options: Available for a wide range of motor sizes and configurations

Product Lineup:

Current Diverter Ring (CDR®): Reliable grounding using conductive filaments and a bronze sleeve

Motor Grounding Seal (MGS®): Combines shaft grounding with bearing protection and contamination control

Smart Ground Monitor™: Real-time monitoring to alert you of reduced grounding performance

Shaft Grounding Solutions

Ideal For:

VFD-driven motors

Industrial pumps, compressors, turbines, and conveyors

Harsh or high-moisture environments

Electric vehicle applications

*Performance is guaranteed—if installed correctly, the system may be covered for up to 5 years, including potential bearing damage protection.

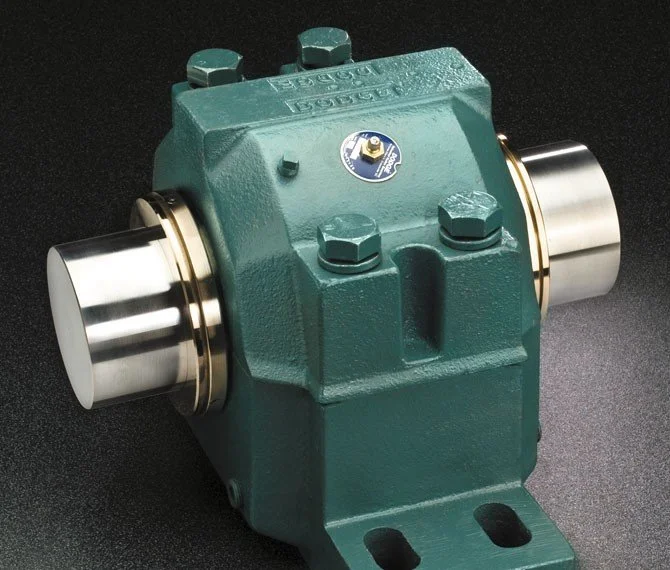

Bearing Isolators

A bearing isolator is a non-contact, non-wearing, permanent bearing protection device. It has a rotor and a stator, and the two are unitized, so that they don’t separate from one another while in use. Typically, the rotor turns with a rotating shaft, while the stator is pressed into a bearing housing. The two components interact to keep contamination out of the bearing enclosure and the lubricant in. The best bearing isolators are made of metal, usually bronze, and they utilize a vapour-blocking feature, which inhibits the free transfer of vapour contamination when the rotating equipment is cycled on and off.

As the inventor of the original bearing isolator, Inpro/Seal continues to be a leading provider of permanent bearing protection for a variety of applications. No matter the size or complexity of the application, Inpro/Seal’s technical experts can design a custom solution for your equipment. Bearing failures lead to expensive downtime and lost production. With Inpro/Seal Bearing Isolators, you can reduce maintenance costs and double the lifetime of your rotating equipment.

Patented bearing isolator design features protect in two ways. Here’s how:

Lubricant is captured in the inner portion of the labyrinth and flows back to the bearing housing.

Outside contamination attempting to enter the bearing housing is captured in the outer labyrinth paths and expelled through a port in the rotor by centrifugal force and gravity.

Features & Benefits:

Permanent, non-contacting, non-wearing bearing protection

Custom-engineered for your application and environment

Easy-install split designs

Patented VBX Ring blocks moisture and condensation

Same-day shipping on most products

Backed by an unconditional performance guarantee

Pillow Block Seal

Pillow blocks are essential for supporting rotating shafts in industrial and power transmission equipment, yet they often cause unexpected downtime due to bearing failure. This is typically the result of contaminants entering the bearing housing or lubrication escaping over time. Although pillow blocks are built for long-term use, traditional sealing methods like LER or LOR rings rely on tight clearances and simple gap-style designs. These seals are ineffective at keeping out dirt and moisture, and they allow valuable lubrication to leak, leading to premature bearing wear.

In some cases, grease-purging is used to create a barrier, but this method is labour-intensive and unreliable. Without consistent upkeep, grease-purged seals lose their effectiveness quickly and leave equipment vulnerable. A more dependable solution is needed to ensure performance and reduce maintenance demands.

The Inpro/Seal Bearing Isolator addresses this challenge by offering permanent protection against contamination ingress and lubricant loss. Its non-contacting design eliminates the wear common with traditional seals and is built to last the entire life of the equipment. This dramatically increases mean time between repair (MTBR), cuts down on maintenance costs, and helps keep operations running smoothly without frequent interruptions. Designed for easy integration into standard pillow block setups, this upgrade delivers consistent, long-term performance without the need for constant greasing or repairs.

FEATURES AND BENEFITS:

Precision-fit stator and rotor connection provides IP66-rated, long-lasting protection from dust, moisture, and debris entering the bearing housing

A built-in contamination chamber captures incoming particles and expels them efficiently using centrifugal force and gravity

A specialized groove design recovers oil from the shaft and channels it back into the housing to reduce lubricant loss

Coalescing rings prevent grease from escaping along the shaft and leaking into the surrounding environment

A compact 45-degree chamber holds the sealing ring in place while reducing the overall footprint of the design

The integrated VBX ring stops vapour contaminants from forming or entering due to temperature shifts within the bearing enclosure