Industrial Equipment Repair & Upgrade Services

Complete reliability enhancement for rotating equipment, pumps, and sealing systems across Western Canada.

Trusted Reliability Experts

For over 45 years, Progressive Sealing has delivered industrial repair and reliability solutions built on better parts, innovative technology, and a century of combined process experience. We specialize in upgrading, repairing, and rebuilding critical rotating equipment to OEM standards.

Our approach combines proven mechanical methods with modern technologies like Chesterton ARC coatings, Mechanical Seals, Inpro/Seal bearing isolators, and EnviroSeals, SpiralTrac™ to improve long-term equipment performance.

Equipment Repair &

Upgrade Capabilities

✔ Pump repair and rebuilds — full tear-down, inspection, and refurbishment

✔ Failure analysis and troubleshooting — root cause diagnosis and metallurgical improvements

✔ Seal chamber and stuffing box enhancement for improved reliability and reduced leakage

✔ Bearing frame upgrades and protection to extend mean time between repairs (MTBR)

✔ Machining, milling, boring, welding, and balancing performed to spec

✔ Advanced wear protection and coating with abrasion and corrosion-resistant materials

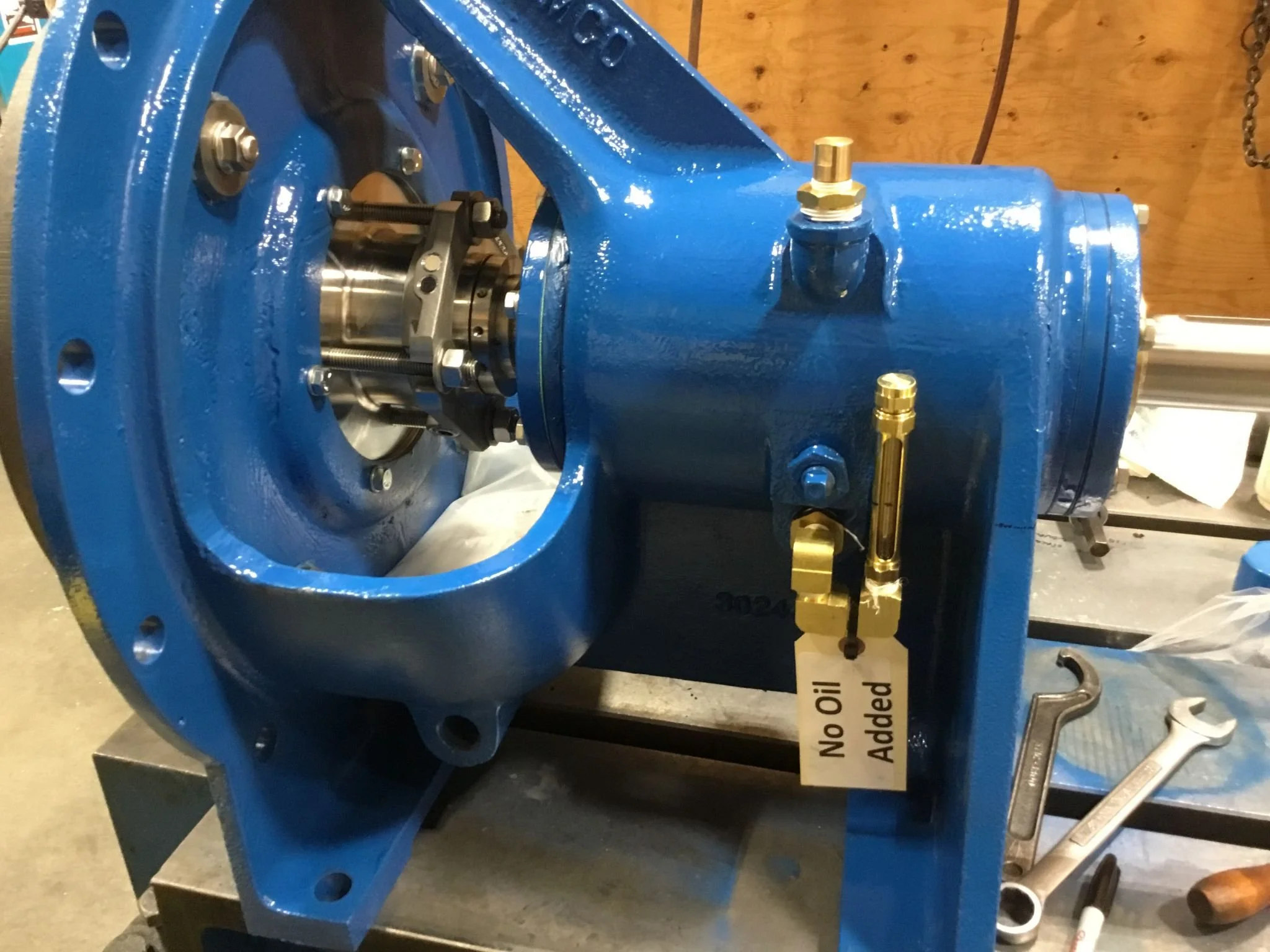

Wemco Torque-Flow Pump Model C

Complete Rebuild & Upgrade

This Wemco Torque-Flow Pump underwent a full teardown and performance upgrade in our Service Department. The unit was rebuilt with upgraded components to reduce wear, improve seal performance, and extend service life in a demanding wastewater environment.

Key Work Completed

Shaft, sleeve, and stuffing box upgrades

Rebuild and precision alignment of the bearing housing

Custom machined parts including upgraded shaft, sleeve, and hardware

Optional high-chrome white iron components for severe-duty conditions

Installed Products

EnviroSeal Engineering Products Ltd. SpiralTrac Seal Version for enhanced seal chamber flow

A.W. Chesterton Company 1810 Mechanical Seal for heavy-duty performance

Inpro/Seal LLC bearing isolators on bearing covers

Built for durability and long-term reliability, this upgraded Wemco pump is ready for years of dependable operation.

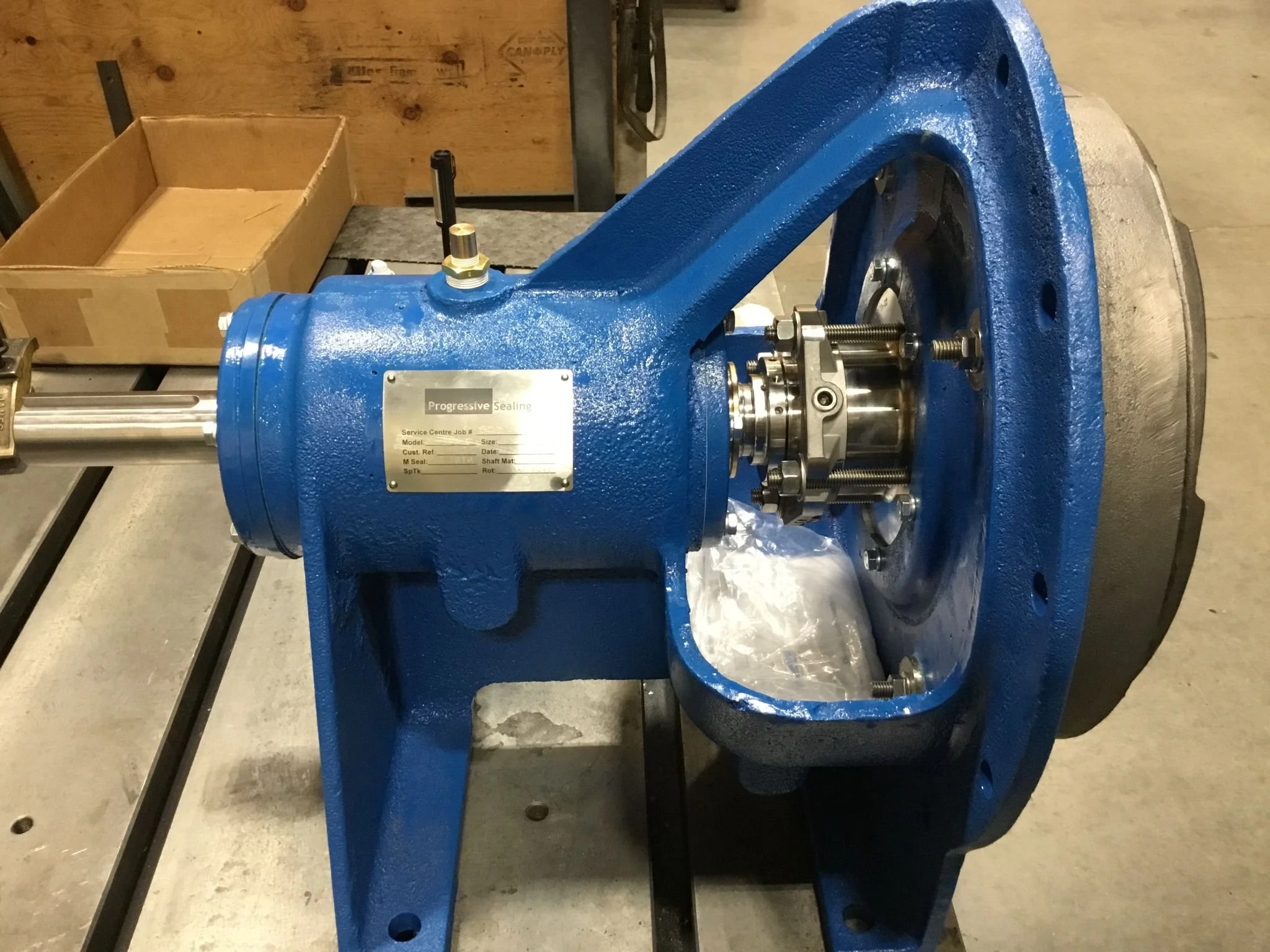

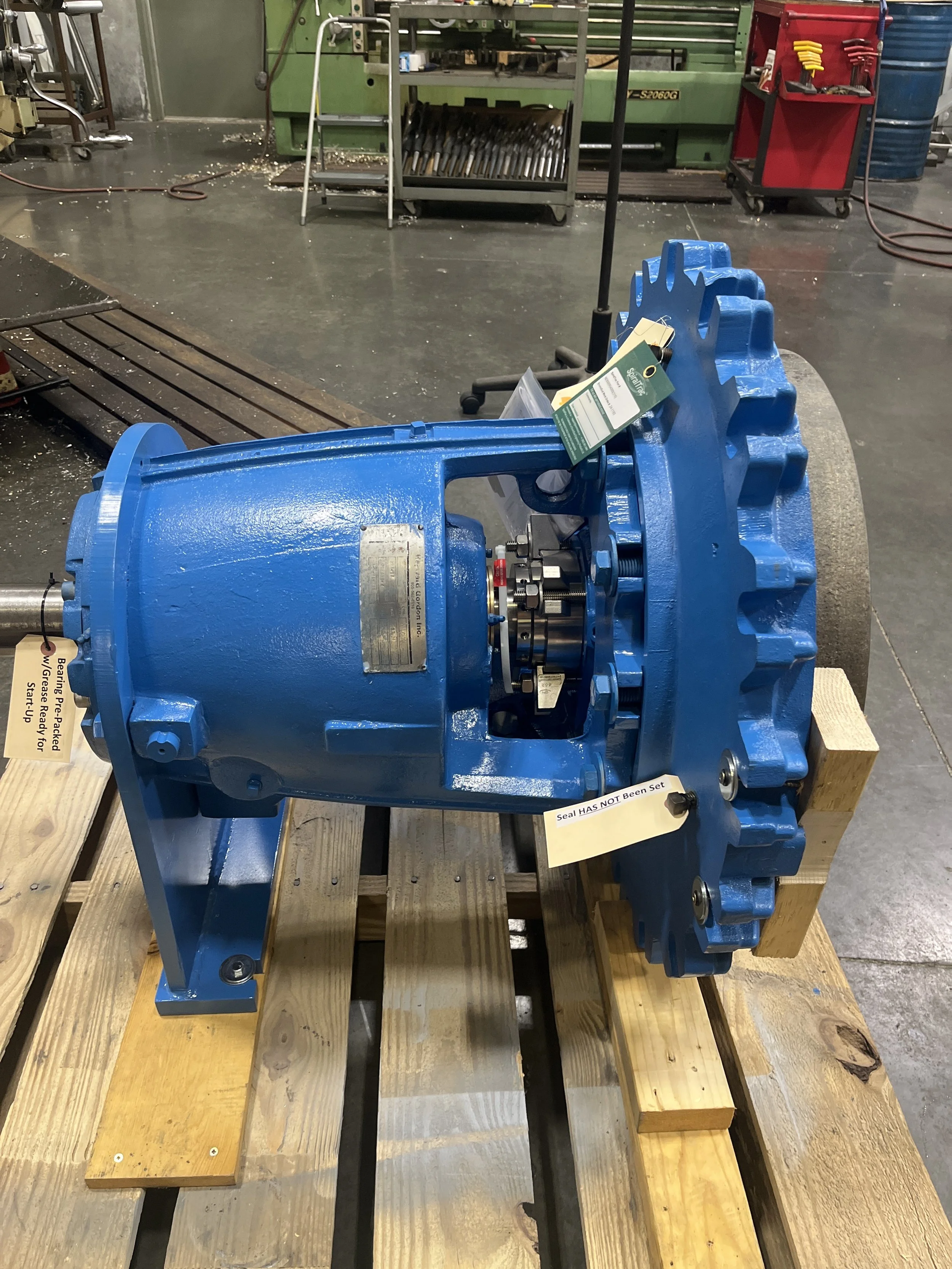

Hayward Gordon X4-12 Pump

Repair & Upgrade

Our team completed a full repair and upgrade of a Hayward Gordon X4-12 pump, returning the unit to reliable service-ready condition. The pump arrived heavily worn and required complete disassembly, inspection, machining, and component replacement to restore performance and extend operational lifespan.

Work Completed

Complete teardown and inspection

Surface preparation and repainting

Machining of worn or damaged surfaces

Replacement of critical hardware

Rebuild and reassembly with upgraded components

Final alignment and functional checks

Results

The pump now meets performance and reliability expectations for heavy-duty wastewater operation, with upgraded components that provide superior resistance to wear and corrosion.

Installed Products

EnviroSeal Engineering Products Ltd. SpiralTrac Seal Version for enhanced seal chamber flow

A.W. Chesterton Company 1810 Mechanical Seal for heavy-duty performance

Inpro/Seal LLC bearing isolators on bearing covers

A.W. Chesterton Company ARC SD4I

Weir 14/12 Pump Back Cover

Upgrade & Repair

Our team completed a full upgrade and repair of a Weir 14/12 pump back cover and stuffing box assembly. The component arrived with severe wear and required complete restoration to return it to operational reliability.

Work Completed

Performed a full teardown and inspection

Completed cleaning, abrasive preparation, and machining

Restored worn surfaces and internal fits

Machined off the original stuffing box from the back cover

Custom-designed and manufactured a new stuffing box from 17-4 HT stainless steel, engineered and heat-treated for exceptional strength and durability. Installed and sealed with A.W. Chesterton Company 860 MPG Moldable Polymer Gasketing

Shrink-fit the SpiralTrac™ system (EnviroSeal Engineering Products Ltd.) to improve seal performance and extend equipment life

Rebuilt surface profiles with A.W. Chesterton Company BX1 due to extreme erosion

Coated the entire bottom wet end with SD4i (A.W. Chesterton Company) to guard against corrosion and wear in demanding slurry applications

Completed precision assembly and final quality checks

Results

The upgraded back cover delivered exceptional return on investment, increasing service life from approximately 3,600 operating hours to more than 28,000 hours—a dramatic improvement in uptime, reliability, and long-term maintenance savings.

That’s more than three times the lifespan, and an additional major benefit: the newly engineered stuffing boxes can now be reused after service instead of being scrapped, further reducing lifecycle costs.

Hoffman Blower

Upgrade & Repair

This Hoffman blower arrived with extensive corrosion, surface wear, and mechanical degradation after long-term industrial service. Our team completed a full upgrade and repair to restore function, improve performance, and extend the blower’s operational life.

Work Completed

Complete disassembly and condition assessment

Shaft material upgrade and replacement

Removal of corrosion and surface contamination

Replacement and coating of worn internal components

Carbon seal replacement and installation of new fasteners and hardware

Full prime and paint for corrosion protection

Final alignment and operational verification

Results

The blower was restored to reliable operating condition with improved durability, sealing and smoother performance. The upgraded components and protective coating provide significantly increased longevity compared to the unit’s incoming condition.

SEALING SOLUTIONS FOR INDUSTRIAL EQUIPMENT

BEARING PROTECTION

PUMP SALES & UPGRADES

INDUSTRIAL COATINGS & LUBRICANTS

CUSTOM PARTS & ENGINEERED SOLUTIONS

industries We Serve

Serving Western Canada’s industrial leaders in:

Mining | Pulp & Paper | Water & Wastewater | Energy | Manufacturing

Why Choose Progressive Sealing:

✔ Over 150 years of combined process experience

✔ Authorized distributor of Chesterton, Inpro/Seal, EnviroSeal, Summit, and Ruhrpumpen

✔ Fast turnaround and on-time delivery

✔ Factory-trained, certified technicians

✔ Proven track record of reduced downtime and longer MTBR