view our product lines | CHESTERTON | INPRO/SEAL | ENVIROSEAL | PUMPS

SpiralTrac®

Proven protection for industrial pumps in harsh conditions

The SpiralTrac Environmental Controller is a unique, patented active throat bushing specially engineered by EnviroSeal to transform and control the internal stuffing box environment in rotating process equipment. With unique versions designed to work with both mechanical seals and packing, SpiralTrac has set the standard in industrial process applications worldwide for increasing equipment reliability, decreasing housekeeping costs, and reducing flush requirements.

SpiralTrac is purpose-built for each application—engineers design hundreds of variations each year to suit specific pumps, seal types, or installation challenges.

Choose between two primary forms:

Seal Version — Works with single, double, or split mechanical seals.

Packing Version — Works with traditional packing systems.

Plus, there’s an Adaptor option for tricky installations, and a wide range of Material Options to match temperature, wear, or chemical needs.

SpiralTrac’s success lies in its uniquely engineered design- by modifying the flows that exist inside rotating equipment, SpiralTrac allows particulate to be removed from the stuffing box (and away from packing and seals), permits air to evacuate the stuffing box during flooding, and minimizes heat buildup in the stuffing box by creating circulation around seal faces.

EnviroSeal Engineering Products Ltd. is a pioneering leader in seal protection technology, offering product families that enhance operating conditions and dramatically increase the service life of mechanical seals and packing in the pulp and paper, mining, API, CPI, municipal, and food processing industries worldwide.

SpiralTrac is a trademark of EnviroSeal Engineering Products Ltd. Not Sure What You’re Looking For? Contact Us

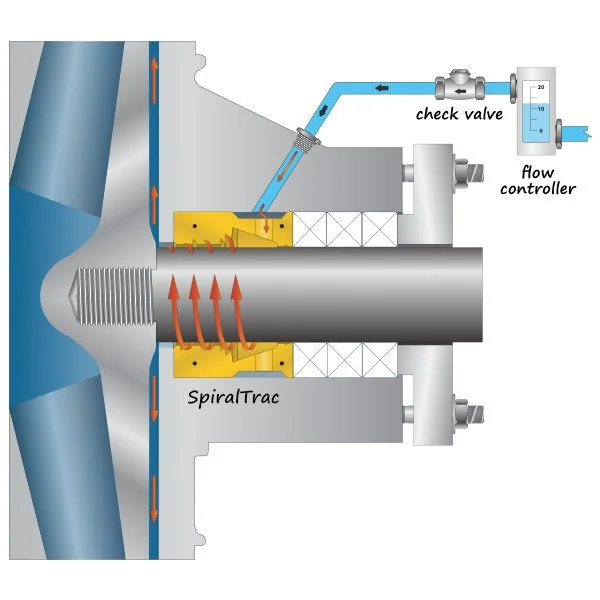

SpiralTrac™ Packing Version (Version P)

What It Is

The SpiralTrac Packing Version is an engineered active throat bushing designed to work with traditional packing in rotating equipment—no pump modifications required. It improves sealing performance, reduces maintenance, and delivers measurable cost savings.

Key Benefits

Cut Water & Flush Costs

Reduce flush water requirementsby 60–80% for immediate water and cost savings.Extend Equipment Life

Keeps abrasives away from the shaft and sleeve, protecting critical components and extending packing life.Cleaner, Safer Operations

Flush leakage is reduced to a clean drip, keeping the work area safe and tidy.Easy to Install

Installs from the gland side with a clearance fit. Works with virtually any rotating equipment.Custom Options

Available in a variety of materials with split or non-split designs to match your application.

How It Works

SpiralTrac uses a patented internal geometry to control fluid flow inside the stuffing box. This design channels abrasives and contaminants away from the packing and shaft, while reducing the amount of flush water needed. The result is longer packing life, less maintenance, and a cleaner, more efficient operation.

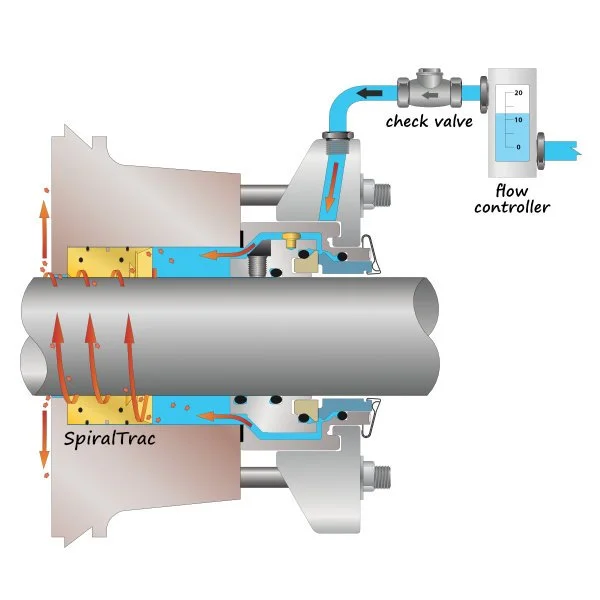

SpiralTrac™ Seal Version

What It is

SpiralTrac for seals is an active throat bushing that transforms the seal cavity environment—ideal for single, double, or split mechanical seals. It reduces contaminants, minimizes flush needs, and helps seals last longer with fewer failures.

key Benefits

Cleaner Seal Environment

Prevents solids and fibers from reaching the seal faces.Extended Seal Life

Increases seal life by 2–6× with less maintenance and downtime.Reduced Flush Costs

Allows for major reductions in flush water use—sometimes eliminating the need entirely.

How It Works

SpiralTrac’s spiral groove geometry channels flow inside the seal cavity to push particulates away from seal faces, circulate cleaner fluid, and—depending on version—vent air or drain residue. The result is a cleaner environment, less erosion, longer seal life, and greater reliability.

-

Type I – Impeller side installation

Type A – Counter bore fit

Type B – Bore fit

Type S – Split

Type E – Externally keyed -

F – Greatly reduced flush

N – Reduced/no flush in non-fibrous media

D – Reduced/no flush in fibrous media

C – With drain for crystallizing media

P – Packing Version used with mechanical packing

Technical Data ↓

-

Carbon Graphite PTFE (ESC)

PPS Blend (MGE)

PEEK Blend (BGE)

Glass Filled PTFE (GLF)

316 Stainless Steel

416 Stainless Steel

17-4PH Stainless Steel (174)

660 Bearing Bronze (BRZ)

Other materials available upon request