custom parts

Is your equipment built for the job?

Create and Maintain Peak Performance with

Progressive Sealing’s Custom Parts Department

OUR TEAM CAN DESIGN AND MANUFACTURE CUSTOM PARTS TO:

✔ Improve Equipment Efficiency

✔ Reduce Lead Times and Downtime

✔ Replace Hard-to-Find or Obsolete Components

✔ Keep Your Equipment Running Longer and Performing Better

BEYOND INDUSTRY STANDARDS

EXTEND EQUIPMENT LIFESPAN

ENJOY SHORTER LEAD TIMES

IMPROVE EQUIPMENT PERFORMANCE BEYOND INDUSTRY STANDARDS

MINIMIZE DOWNTIME

ACCESS INVENTORY ON DEMAND

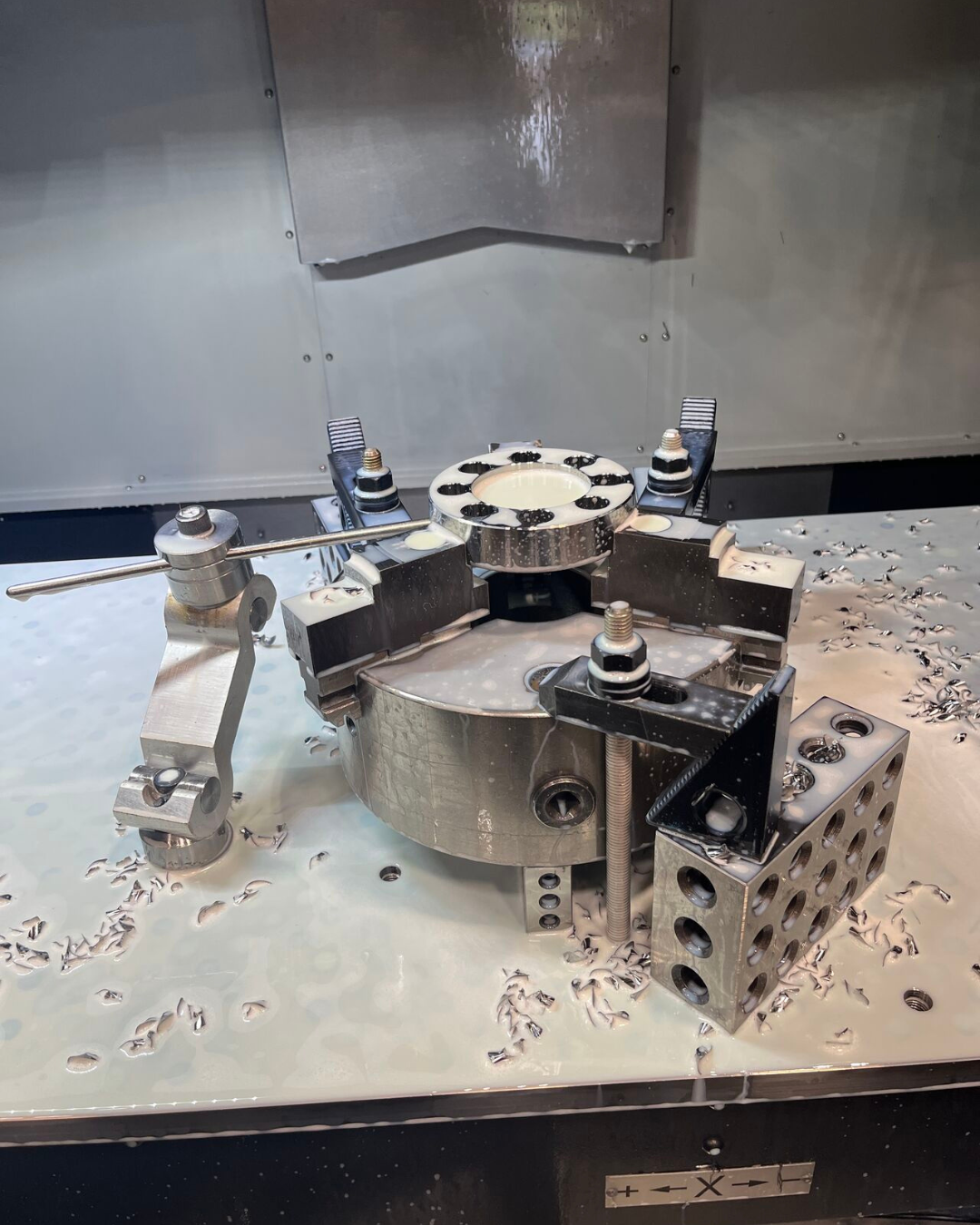

Super-Bolt Tool

Custom Machining and Production

Our customer was experiencing fatigue while removing Supernuts (SuperBolts) after loosening the nuts, they still had to spin them off manually over multiple threads.

Our Solution:

We developed a custom tool that attaches to an impact driver, allowing quick and efficient removal of the nuts without manual effort.

Work Completed

3D design and modeling based on customer requirements

In-house engineering collaboration to address ergonomic fatigue

Development of an impact-driver attachment for quick Supernut removal

CNC machining, precision drilling, and dimensional finishing

Prototyping and field testing with the customer

Production of multiple identical tools

Results

A safer, faster, and more ergonomic maintenance process for our customer.

4140 Steel Lugs

for a Marine Customer

Our machine shop produced a run of precision machined 4140 steel lugs for a marine industry customer. These components were designed to withstand high load conditions and demanding operating environments that are common in marine applications.

Work Completed

Material selection and preparation using 4140 alloy steel

Precision CNC Turning of each lug to the required dimensions

Finishing of contact surfaces for smooth installation

Quality inspection for consistency across the full production batch

Purpose and Applications

4140 steel lugs are used in heavy marine assemblies that require strength, durability, and resistance to wear. These parts are often integrated into lifting systems, mounting hardware, structural connections, and vibration resistant assemblies.

Results

The completed lugs were delivered with a polished finish, tight dimensional accuracy, and consistent quality across the entire batch. The components were ready for immediate use in a marine environment.

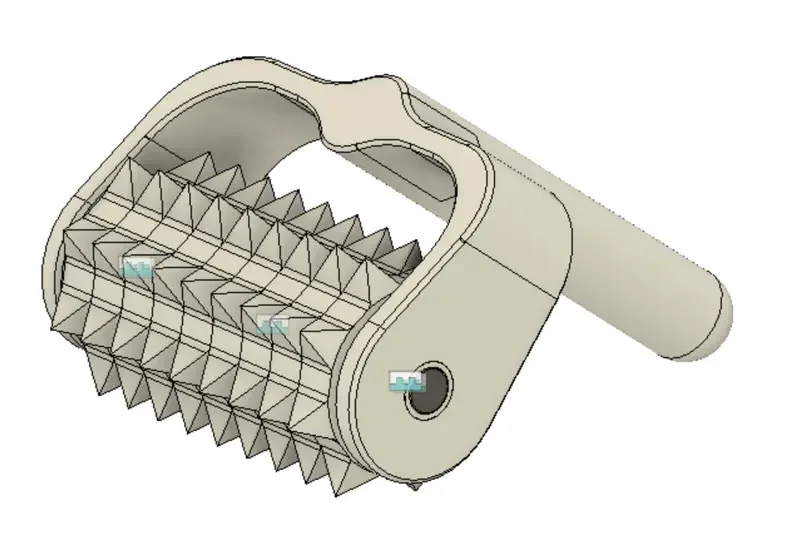

Pizza Dough Docker Handle

Redesign for Improved Safety and Performance

A commercial kitchen client needed a more efficient and ergonomic way to dimple pizza dough. Their staff were manually dimpling the dough, causing wrist strain and requiring multiple employees per day to keep up with production.

The customer brought our team a rough prototype that we re-engineered into a full product and food-safe design.

The redesigned handheld docker had better ergonomics, an easy to clean toolless design and a simplified integrated handle to reduce cost.

What We Did

Identified stress points and expensive fabrication in the original handheld tool

Designed a more ergonomic 3D-modeled handle

Strengthened the roller attachment for heavy-duty use

Produced prototypes and finalized food-safe production units

RESULTS

In high-volume kitchens, repetitive dough preparation can lead to strain and slowdowns.

The improved handheld design reduced fatigue, while the dough docker eliminated manual dimpling and increased daily throughput.

UNLOCK YOUR BUSINESS' FULL POTENTIAL

LET OUR TEAM OF EXPERTS DELIVER TAILORED SOLUTIONS THAT WILL

ELEVATE YOUR OPERATIONS, BOOST PRODUCTIVITY AND DRIVE LONG TERM SUCCESS.

Step #01

Contact our team and share your problem.

FOR RE-ORDERING, GO TO STEP 03!

OUR EASY 5-STEP ORDERING PROCESS

Step #02

We will assess your problem and create a custom solution.

Step #03

Place Your Order

Step #04

Your custom parts are delivered.

Step #05

We keep your custom parts in stock to make ordering easy.