Equipment Monitoring Solutions

Real-Time Data. smarter solutions. better reliability.

Still relying on manual checks or reactive maintenance?

Chesterton’s equipment monitoring solutions help you identify problems before they become failures — reducing downtime, improving safety, and maximizing asset performance.

What we Do

Chesterton Connect™ and Chesterton Connect™ Cloud offer a powerful, scalable solution to monitor rotating equipment like pumps, mixers, and agitators in real time. By continuously tracking key performance data and sending alerts before failure, you can shift from reactive to predictive maintenance — saving time, reducing costs, and preventing surprises.

Our Capabilities Include:

✔ Bluetooth-Enabled Monitoring Devices

Easily installed sensors provide real-time insight into temperature, vibration, and pressure.

✔ Cloud-Based Equipment Monitoring

Monitor your assets remotely, across multiple locations, through a secure, web-based dashboard.

✔ Predictive Maintenance Support

Use data trends and thresholds to identify issues early and schedule maintenance before failure.

✔ Multi-Asset Data Tracking

Review the performance of pumps, seals, motors, and other components — all in one place.

✔ Secure Alerts and Reporting

Get email and mobile notifications when performance parameters exceed safe limits.

What we offer:

✔ Wireless, battery-powered monitoring devices

✔ Real-time access to equipment health data

✔ Integration with existing maintenance strategies

✔ Easy-to-install systems (no wiring or IT support required)

✔ Secure, remote cloud access to all connected devices

✔ Data storage, trend tracking, and performance analysis tools

systems WE use

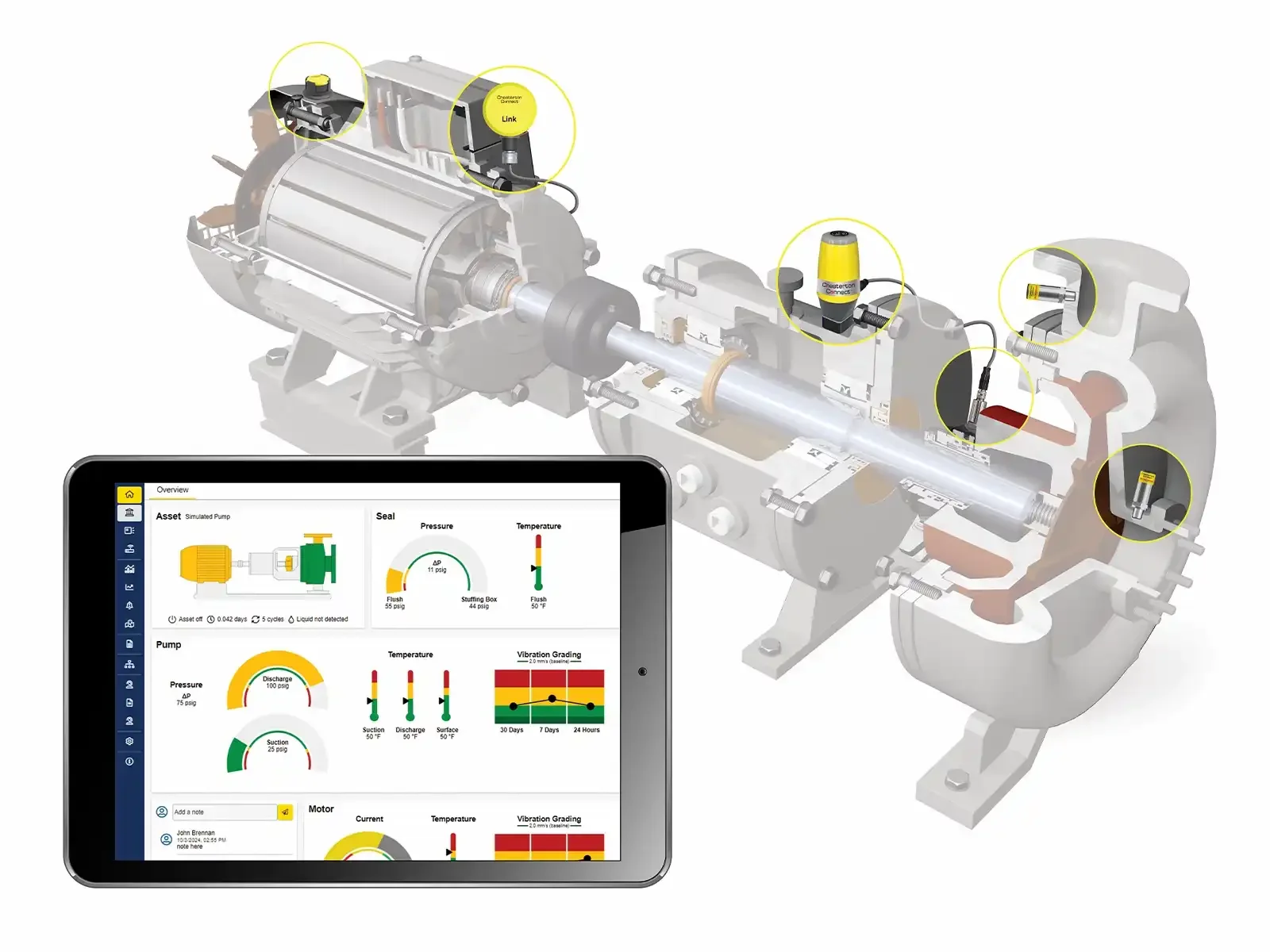

Chesterton Connect™

Chesterton Connect is a compact, wireless sensor that attaches to your rotating equipment to monitor vibration, surface temperature, pressure, and equipment run-time. Using Bluetooth technology, data is collected and shared via mobile app or synced to the cloud — giving maintenance teams instant visibility into asset performance.

✔ Installs in minutes — no wiring or IT needed

✔ Provides local and remote data access

✔ Helps detect conditions like cavitation, misalignment, and dry running

✔ Supports proactive, data-driven maintenance

Smart Monitoring at the Equipment Level

chesterton connect™ cloud

Chesterton Connect Cloud expands your monitoring capabilities with a secure, web-based platform that aggregates data from multiple Connect sensors. From any device, you can review trends, compare performance, and trigger alerts — across a single site or multiple global locations.

✔ Manage multiple assets from one dashboard

✔ Custom alerts and email notifications for abnormal conditions

✔ Secure data logging, trending, and export

✔ Ideal for enterprise reliability programs

Cloud-Based Visibility for Plant-Wide Performance

PARTNER WITH PROGRESSIVE

✔ Certified Chesterton Partners: We provide authorized installation, setup, and support for Connect systems.

✔ Real-Time Reliability: With live equipment insights, you’ll never be caught off guard again.

✔ Quick ROI: Lower maintenance costs, fewer failures, and more uptime — all with a fast, affordable setup.

✔ Flexible Integration: Connect systems work with existing equipment and workflows, no major upgrades required.

✔ Smart Maintenance Starts Here: Move beyond the clipboard and start managing your assets with real-time intelligence.