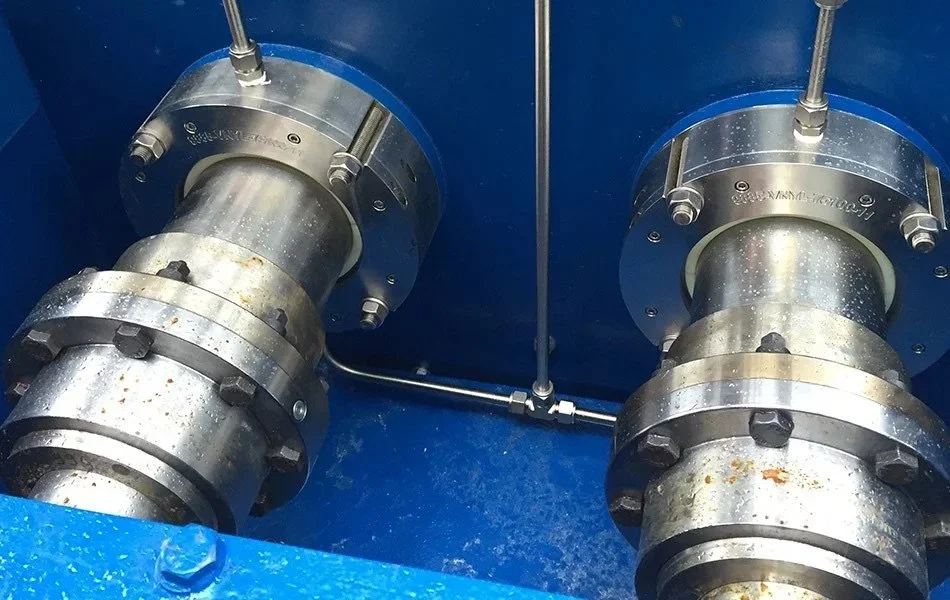

air mizer shaft seals

Product leakage and contamination are common challenges in industrial process equipment, often resulting from unreliable or outdated sealing methods such as mechanical packing, lip seals, or traditional mechanical seals. These contact-based seals are prone to wear over time due to continuous shaft rotation, misalignment, vibration, and thermal expansion. When seals fail, facilities face increased maintenance requirements, unplanned downtime, higher production costs, and potential safety or environmental hazards, particularly when handling hazardous, corrosive, or sensitive materials. Ensuring reliable sealing is critical to maintaining operational efficiency, protecting personnel, and safeguarding the environment.

Air Mizer® shaft seals provide a dependable, long-lasting, and maintenance-free solution for sealing powders, liquids, slurries, and bulk solids across a wide range of industrial applications. Their advanced non-contact, fully articulating design automatically adapts to radial run-out, axial movement, and angular misalignment, eliminating product loss and preventing contamination from entering either the equipment or the surrounding environment. Unlike traditional seals, Air Mizer® seals do not experience wear from friction, ensuring consistent performance over the life of the equipment.

These permanent seals are engineered to improve operational efficiency, reduce maintenance interventions, extend production uptime, and enhance workplace safety. They are suitable for challenging applications in chemical processing, pharmaceuticals, food production, mining, pulp and paper, and other industries that require reliable containment of powders, slurries, or liquids. By implementing Air Mizer® shaft seals, facilities can achieve consistent, dependable sealing performance, minimize environmental and safety risks, reduce long-term operational costs, and maintain continuous, efficient production in demanding industrial environments.